Printing

- Home

- Printing

Material Science & Resin Innovation

We begin with science. Our approach to material selection is driven by performance, sustainability, and innovation. By engineering custom resin blends and working with a range of polymers, we create optimized packaging films tailored to specific product needs — offering strength, clarity, flexibility, and environmental responsibility from the very first layer.

Extrusion

At Billion Flex, we specialize in blown film extrusion — a process where melted plastic is shaped into a sleeve and expanded with air to form high-quality films. Our advanced technology and expertise allow us to produce a wide range of durable, precision-crafted blown films.

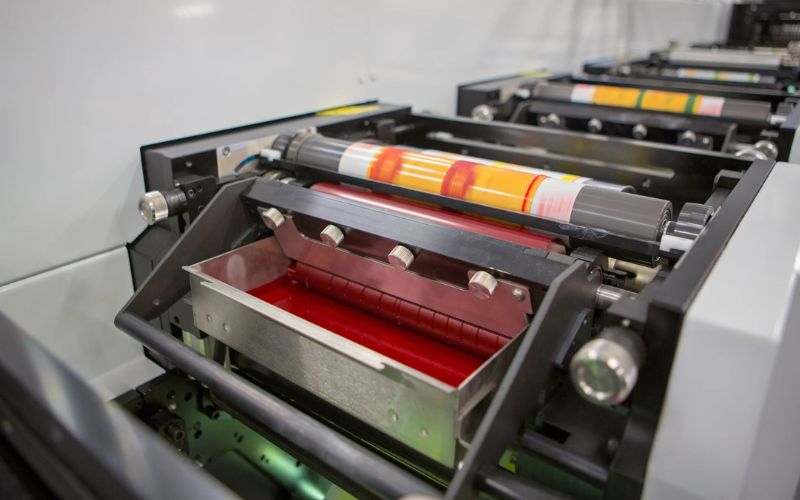

Flexographic Printing

Flexographic (Flexo) printing is a high-quality, cost-effective method ideal for films, shrink sleeves, and flexible packaging. Using photopolymer plates and anilox rollers, it delivers sharp, consistent prints with quick setup and minimal waste. Its flexibility makes it perfect for short runs and frequently changing designs aligned with dynamic marketing needs.

Rotogravure Printing

Gravure printing at Billion Flex delivers exceptional print quality with precision and consistency. Using engraved metal cylinders, our rotogravure presses reproduce intricate designs in up to ten vibrant colors — ideal for high-volume packaging like carry bags, shrink sleeves, and wraps. Perfect for detailed images and metallic finishes, gravure ensures brilliant color and premium visual impact.